Wet Bench Optional Features and Services

- Emergency Power Off circuit with remote mushroom switch locate in accessible areas on front and rear of the wet bench weldment.

- Isolated electrical controls located in purged/pressurized compartments with access interlock switches to de-energize the tool electrical power when opened.

- All UL, CE and CSA or equivalent listed electrical components, load center and contactors.

- All wet bench electrical circuits and electrical components are individually protected by fuses or circuit breakers and all heater power circuits are protected by GCFI circuit breakers.

- Digihelic low exhaust indicator with audible and visual alarm indicator and Emergency Power Off interface.

- Wet bench secondary plenum liquid level monitor with audible and visual alarm indicator and Emergency Power Off interface.

- Auto D.I. water shutoff in the event of a wet bench Plenum Liquid Level Alarm or Emergency Power Off circuit condition.

- Redundant high temperature limit heater safety controls and thermal cut off devices on all heated process vessels.

- Liquid level interlocks on all heated and recirculated chemical process vessels.

- Meets or exceeds solvent wet bench process Freeboard requirements for all High VOC chemical processes and meets the Bay Area Bay Area Air Quality Management District regulations.

- Class 1, Div. 2 design for all solvent wet bench flammable chemical processes.

- CO2 or DI Water / N2 Fine Water Mist wet bench flame suppression systems with dual mode UV/IR flame detectors using all Fsub-assemblies on components and reviewed by a third party for coverage calculations.

- Wet bench optional features and services for our weldments incorporate removable front, side and rear access panels with interlock switches to interface with EPO circuit for servicing plumbing, electrical and positioning system components. Positioning system is incorporated into an isolated compartment for easy access for servicing out of clean room operation area is a service chase.

- Recessed or flat work deck with 360° process vessel lip exhaust to insure capture of fumes from chemical vessels during transfer of wafers.

- Reduced wet bench exhaust requirements equate to reduced clean room make up air which reduces facility operation cost.

- Integral inner back wall exhaust dampers with exhaust transition and wax coated industrial water sprinkler head to interface with facilities exhaust system and house fire sprinkler system.

- Modular design facilitates wet bench process vessel reconfiguration if chemical process changes are necessary.

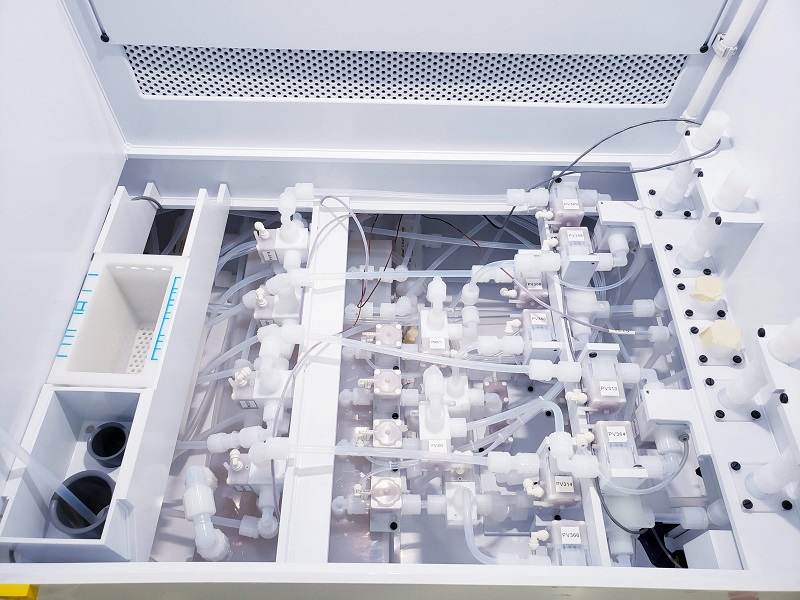

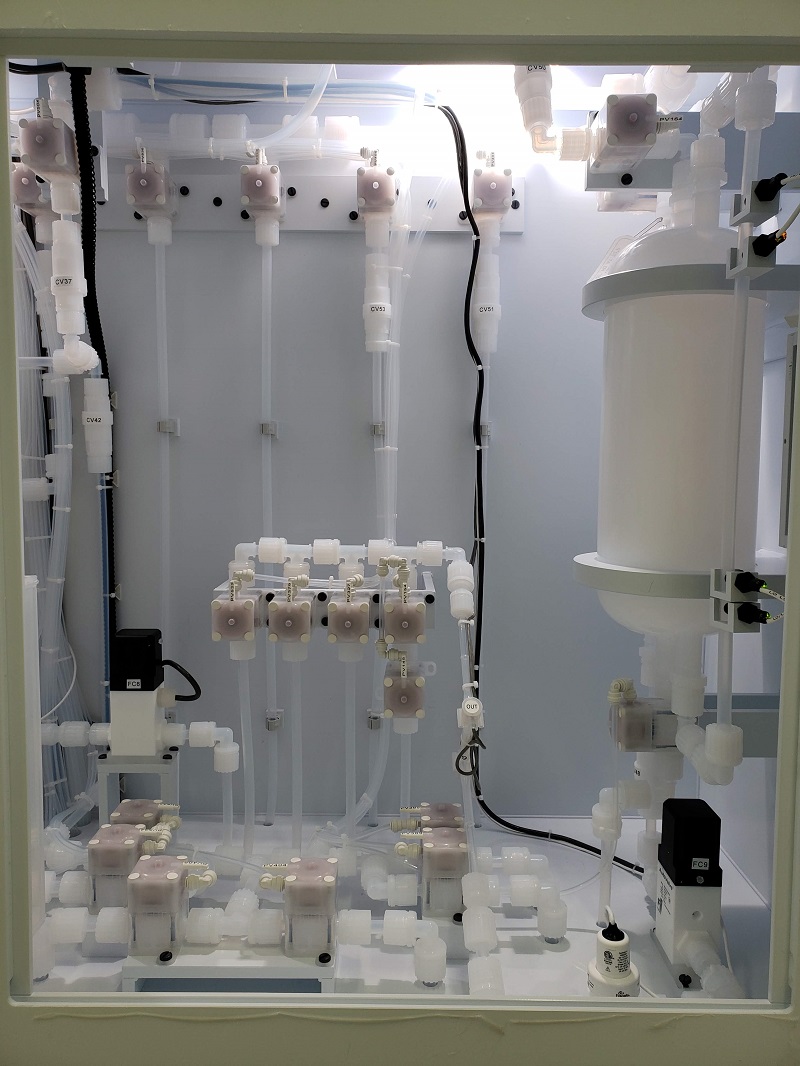

- Flow through PFA Teflon DI water manifold with PFA Teflon tube fittings and PFA Teflon pneumatic diaphragm valves.

- All chemical and rinse process vessel wetted components are constructed of Quartz, PVDF, PTFE Teflon or PFA Teflon.

- Clear CPVC front safety shields protect the operator while reducing the wet bench front fume capture zone reducing the overall area which must sustain a specific face velocity.

- Corrosion resistant casters and leg levelers permit ease of transportation to point of installation.

- Flame retardant CPVC or PVC-C.

- PVDF (Polyvinylidene Fluoride).

- Halar / ECTFE (Ethylene Chlorotrifluoroethylene).

- 304 #4 brush or 316L stainless steel weldment with mirror polished finished is used for all Organic Solvent processes.

- Automatic Bulk Chemical Dispense.

- Vertical HEPA or ULPA laminar flow air filtration.

- Multi Axis Positioning Systems Independent 90 VAC five phase servo positioning systems for each module.

- Process Sequence Data Logging. Data Logging is performed at each event during the process and provides complete records of process data for each lot of wafers which is processed through wet bench.

- Run Time Entries. All the following entries will be logged into Data Logger as each event occurs during wafer lot processing.

- Operator Name And Identification. This data is entered at “Sign On” screen. Software will “Look Up” operator name from programmed directory.

- Batch ID Lot Number. This data is entered at “Batch Identification Screen.” Operator will input Alpha-Numeric or Numeric Integer used to identify Lot of Wafers being processed.

- Recipe Name. This data is entered at “Recipe Select Screen.” Operator will input Numeric code used to identify recipe process parameters. All parameters, including “Recipe Name” will be downloaded to PLC for that particular process.

- Chemical Data. This data is entered at “Chemical Edit Screen” in which the chemical technician will input Manufacturers Name, Manufacturers Lot Number, Chemical Ratio and Date of Last Chemical Change.

- Temperature Data. Entered into data logger as each event occurs during the process sequence.

- Alarm Data. All alarm date will be logged to the “Alarm Review Screen” on the PLC touch screen. As well all alarm conditions will be logged to the data logger for reports and are accessed in the “Alarm Report” data file of the data logger.

Wafer Process Systems Inc. also performs in field modifications to existing wet benches to accommodate process changes and/or safety and upgrades for our customers’ without the need of extensive cost associated with the removal of existing equipment and installation of new equipment.